Sophisticated Analysis technique

Computational Fluid Dynamics (CFD) is a technology that uses computer software to analyze and solve problems that involve fluid flows. It is a sophisticated analysis technique that not only can predict fluid flow behaviour, but also heat and mass transfer, phase change, chemical reactions—including combustion, mechanical movement, and the stress or deformation of related solid structures.

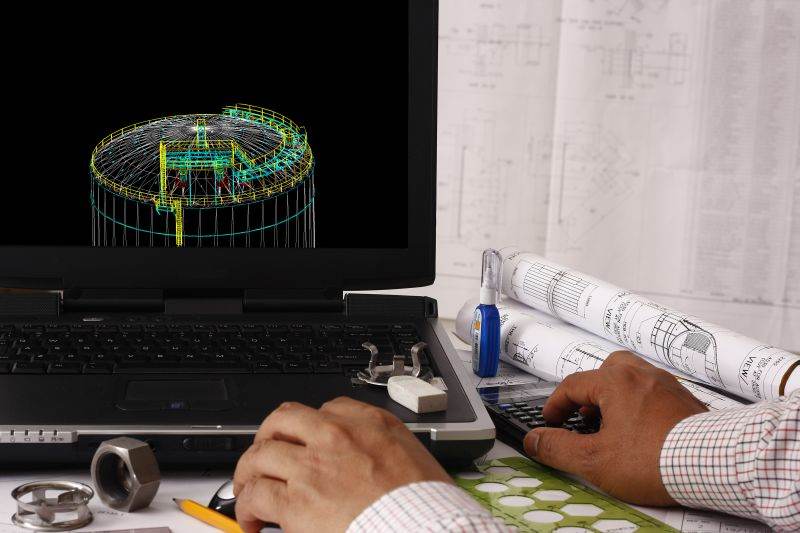

Using CFD, a geometric computer model is built that represents the system or device to be studied and then fluid flow physics (including boundary conditions and fluid properties) are applied to this virtual prototype; the software outputs a prediction of the fluid dynamics.

vessel inlet simulation

Coanda's 900+ core server cluster

There are three compelling reasons to use CFD:

Insight

Many devices and systems are very difficult to prototype or too dangerous to analyze in a laboratory. Often, CFD analysis reveals parts of the system—or phenomena happening within the system—that would be unattainable through any other means. CFD provides a means of visualizing the system and gives an enhanced understanding of the fluid process.

Foresight

Because CFD is a tool for predicting what will happen under a given set of circumstances, it can answer many ‘what if?’ questions. In a relatively short time, design performance can be predicted and many variations tested in order to obtain optimal result. All of this is done before physical prototyping is required and testing is initiated.

Efficiency

Better and faster design or analysis leads to shorter design cycles. Time and money are saved, products get to market faster, and equipment improvements can be built and installed with minimal downtime. CFD is a tool for compressing the design and development cycle.

Capabilities

Coanda offers exceptional capabilities in CFD for flow field analysis, equipment design and process optimization. With seven Ph.D. level team members, Coanda’s CFD group has hundreds of successfully completed projects under its belt. These span the areas of multi-phase flows, reacting and combusting flows, turbomachinery, non-Newtonian flows and highly compressible flows amongst others. Furthermore, Coanda is unique in its ability to complement CFD studies with experimental validation through our physical modelling services.

Infrastructure

Coanda maintains a High Performance Computing (HPC) Linux cluster with over 900 cores (and growing) connected through InfiniBand. CFD simulations are primarily conducted using ANSYS Fluent™ and model development with Dassault SolidWorks®.